Removing paint or coating with induction stripping

The innovative RPR System is a highly effective and highly efficient method to remove anti-corrosion products such as paint, epoxies and fire retardant coatings from metal surfaces.

The patented system based on inductive heating is a proven and reliable technique and offers a cost-effective and environmentally friendly solution for surface treatment.

The patented system based on inductive heating is a proven and reliable technique and offers a cost-effective and environmentally friendly solution for surface treatment.

What is induction stripping and how does it work

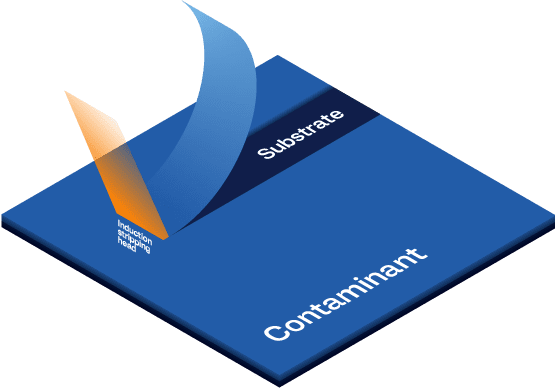

When the system is on, the power supply sends an alternating voltage through a coil. The resulting magnetic field in the head gives off a precisely dosed amount of heat that ensures the correct temperature of detachment of the paint without having direct contact with the surface (no wear on the head).

Remaining the same settings of the system ensures equal inductive heating and produces constant and reproducible results for the speed of paint stripping. The temperature is generated in the metal surface under the paint layer and the detachment between carrier and coating immediately follows from this. The dosing of the energy is very focused.

Heat is generated only on the steel surface and in the head of the system, resulting in the removal of the paint while the environment remains unaffected.

After implementation, we ensure that the waste is disposed of in accordance with any agreements. Thanks to this innovative technique, there is no other waste besides the removal of the product.

Download technical information

Curious about the technical information behind induction stipping or the equipment we work with?

Download now (Dutch)

Curious about how induction stripping works?

Watch this video as an example or request a demo for your company.

Request a demoVideoWhat are the benefits of induction stripping

- Induction stripping is a fast method for removing industrial, hard-to-remove coatings (up to 30mm thick) from steel surfaces

- Induction stripping produces no secondary waste besides the removed coating. This in contrast to, for example, sandblasting. This significantly reduces costs

- Induction stripping is not only more sustainable, but also much quieter. No sound is produced by the equipment.

- This method is very energy efficient. Unlike alternative methods, induction stripping uses only 25% of the energy.

Request a demo for induction stripping

Are you curious about the possibilities of induction stripping for your organization? Then request a demo.

Request a demoLaser cleaning is the new and innovative approach to surface treatment, for cleaning rust, paint or other pollution. Where traditional abrasive or chemical methods cause problems, there is no waste during laser cleaning work and the cleaned surface comes very close to the original finish.

Pieter de Mol, Dutch Decoating