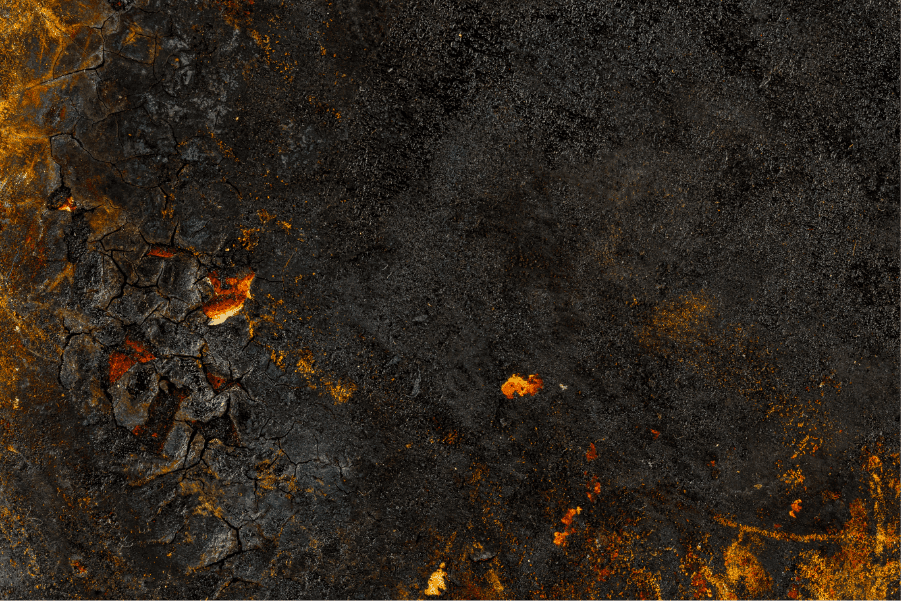

Removing soot from fire with laser clearing

When there has been a fire, soot often remains on machines and surfaces. To clean these, laser cleaning is an excellent, durable and fast solution.

Laser cleaning for soot caused by fire

Fast and durable cleaning without dismantling

Laser cleaning or laser cleaning is a modern cleaning technique. The advantage of laser cleaning for soot after a fire is that it removes deposits on vulnerable surfaces without damaging these surfaces. Because the laser evaporates the soot, no waste remains, which speeds up the cleaning process.

More about lasercleaning

What are the advantages of laser cleaning for soot caused by fire?

- With laser clearing you can clean surfaces without (further) damage to the surface or parts.

- Laser cleaning means cleaning without residue, water or waste. So sustainable and environmentally conscious.

- Laser clearing does not use any chemicals or abrasives

- Also works great for machines and machine parts without having to remove them.

- Laser cleaning can be done at your location, so that nuisance is kept to a minimum and no transport is required.

Request demo

Are you curious about the possibilities of laser cleaning for your situation? Feel free to contact us or request a demo.

Request demoLaser cleaning is the new and innovative approach to surface treatment, for cleaning rust, paint or other pollution. Where traditional abrasive or chemical methods cause problems, there is no waste during laser cleaning work and the cleaned surface comes very close to the original finish.

Pieter de Mol, Dutch Decoating